Advanced Electronics Technician

Advanced Electronics Technician

| Name of the Course | : | Advanced Electronics Technician |

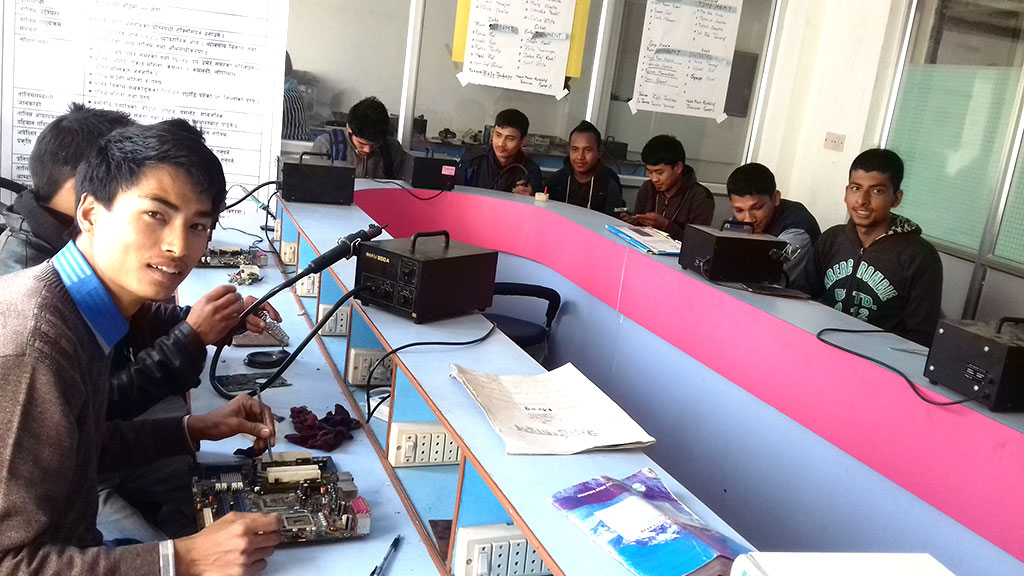

| Length of Course | : | 24 days ( 2 hours per day total 48 hrs.) |

| Group Size | : | Maximum 10 Person |

| Theory Practical Ratio | : | 20% and 80% |

| Entry Criteria | : | Interview |

| Eligibility | : | Literate/Fresher can apply |

| Facilities | : | Sufficient Tools equipment and training materials will provide by Tps. |

| Trainers | : | CTEVT certified trainers 10:1 |

| New Class | : | Nepali 1 gate and 15 gate. (If holiday falls on that day than next day will start the new class) |

Course Objectives

After completion of this course, you will able to elementary level of troubleshooting and repairing, all kind of electronics equipment such as SMPS power supply, Welding machine, Jogger machine, Electric kettle, induction cooker, Microwave woven, Washing machine, Freeze AC and Electric Vehicle control board etc.

Course Subjects

- Safety and precautions Electronics /circuits and lab management.

- Checking of Components review of basic components.

- Identify and checking of VDR, Thyristor and Triac

- Functions and differentiate of Regulated and unregulated power supply.

- Design and assemble a linear regulated power supply.

- SMPS power supply block diagram, Understand how switch mode power supply (SMPS) work (Fly back-converter Topology)

- Function of SMPS, section wise descriptions,

- Identify the components, using in SMPS Thermistor, Opt coupler, MOSFET MOV, IGBT,

- checking of SMPS components such as Thermistor, Opt coupler, MOSFET MOV, IGBT comparison types ,and datasheet

- Types of SMPS descriptions, as circuit diagrams

- Measuring in put supply voltages

- Trace cold line test reading Schematic Diagram

- Tracing of input circuit

- Hot line test and measurement, Measurement of input supply voltage

- Tracing of output circuit, Rectifier, filter and error amplifier circuits.

- Hotline test, Reading of output voltage,

- Identify the section wise components, checking of components and finding the faults.

- Identify the SMD components,

- Identify the value of SMD components, checking of SMD components.

- Use of SMD rework stations

- Checking of input circuits, sensor circuits, output rectifier and filter circuits and checking of control Frequency.

- Reading schematic diagram, step by step tracing and understanding functions of different sections.

- Step by step Trouble shooting and repairing of SMPS

- Use DC A meter, light bulb, and flickering method to isolate power supply problems this speeding up the repair process.

- Checking of different types of SMPS, charger, TV, Monitor and LED TV SMPS.

- Checking of SMPS with proper load, using watt meter and current meter.

- Deliver the troubleshooting Technique for different Electronics Equipment.